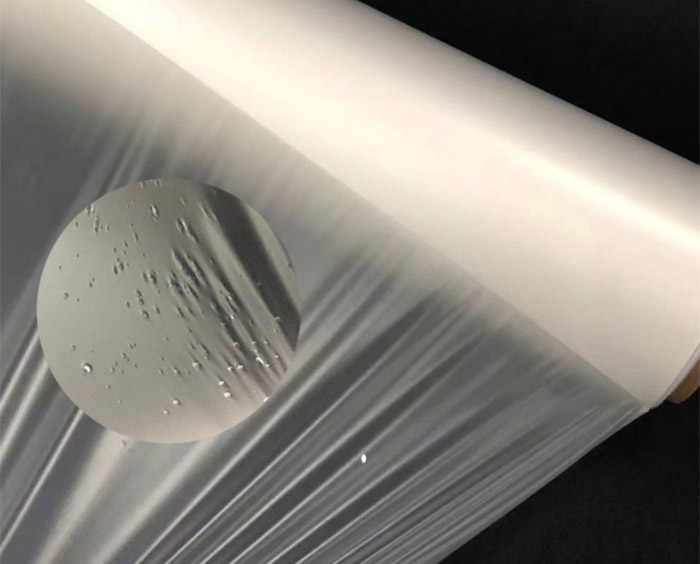

Processing methods: Blow molding、Casting

Features: High moisture permeability, excellent temperature resistance, stable processing, high water pressure retention after lamination, customizable anti-phenol yellowing

Applications:Outdoor sports, windowbreakers, down jackets, medical consumables, etc

| Item | Density | Hardness | Tensile Strength | 100% Modulus | 300% Modulus | Elongation at Break | Water vaper transmission rate | Feature |

|---|---|---|---|---|---|---|---|---|

| Standard | ASTM D792 | ASTM D2240 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM E968w 2000(1.5斯) | |

| Unit | g/cm3 | Shore A | Mpa | Mpa | Mpa | % | g/m2 /24h | |

| 7231 | 1.20 | 75A | 15 | 4 | 6 | 800 | 10000+ | Ultra-high transparency 75A |

| 7242 | 1.20 | 78A | 22 | 5 | 8 | 850 | 10000+ | Ultra-high transparency 80A |

| 7241 | 1.20 | 80A | 25 | 5 | 8 | 850 | 9000+ | Temperature resistance and high permeability |

| 7285 | 1.20 | 85A | 27 | 6 | 10 | 750 | 9000+ | Temperature resistance and medium to high permeability |

| 7262 | 1.21 | 90A | 32 | 8 | 12 | 660 | 7500+ | Temperature resistance and transparency |

| 7280 | 1.20 | 80A | 25 | 5 | 9 | 900 | 7500+ | |

| 7290 | 1.21 | 88A | 30 | 7 | 11 | 700 | 7500+ | Medium penetration 90 |

| 7295 | 1.21 | 93A | 32 | 8 | 14 | 650 | 7000+ | Medium penetration 95 |

| 7298 | 1.20 | 95A | 35 | 9 | 17 | 600 | 9000+ |

Note: The above values are shown as typical values and should not be used as specifications.