Features: Ether/Ester, Halogen-free Flame Retardant, Excellent Hydrolytic Resistance, Low Temperature Flexibility, Abrasion Resistance.

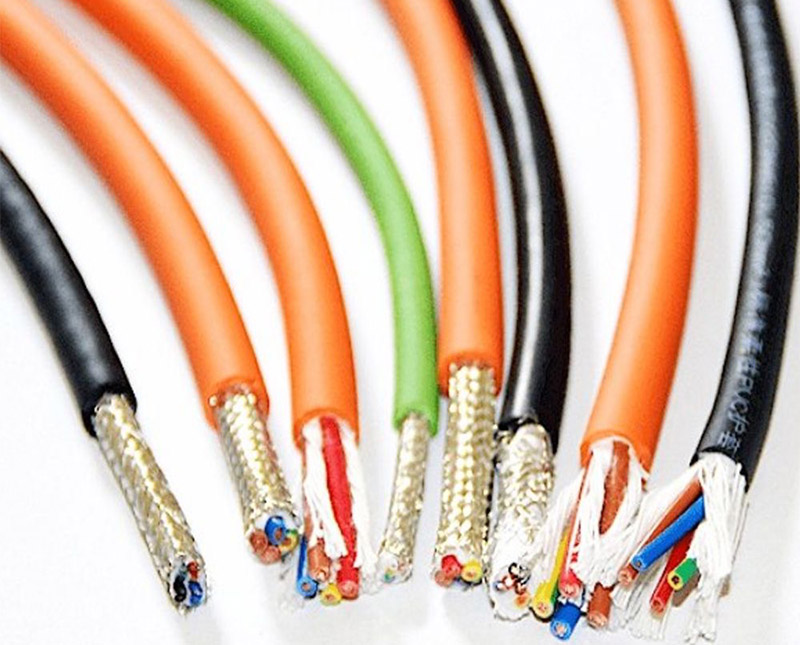

Applications: Cable & Wire, Film, Tube, Injection etc.

| Properties | Density | Hardness | Tensile Strength | 100% Modulus | 300% Modulus | Tear Strength | Elongation at Break | Tg | FR Property |

|---|---|---|---|---|---|---|---|---|---|

| Standard | ASTM D792 | ASTM D2240 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D624 | DSC | UL94 |

| Unit | g/cm3 | Shore A/D | MPa | MPa | MPa | % | KN/m | ℃ | -- |

| L380FR | 1.23 | 84 | 25 | 7 | 10 | 90 | 500 | -35 | V-0 |

| L385FR | 1.23 | 85 | 30 | 10 | 12 | 95 | 400 | -30 | V-0 |

| HT390FR | 1.24 | 93A | 35 | 12 | 15 | 110 | 350 | -25 | V-0 |

| HT480FR | 1.15 | 80A | 23 | 7 | 11 | 80 | 500 | -40 | V-2 |

| HT485FR | 1.15 | 87A | 28 | 10 | 15 | 90 | 400 | -45 | V-2 |

| HT490FR | 1.2 | 90A | 32 | 13 | 18 | 100 | 350 | V-2 |

Note: The above values are shown as typical values and should not be used as specifications.

Features: Ether/Ester, Low resistivity, low precipitation, excellent physical properties

Applications: Film, Tube, Injection etc.

| Properties | Density | Hardness | Tensile Strength | 100% Modulus | 300% Modulus | Tear Strength | Elongation at Break | Electrical resistance |

|---|---|---|---|---|---|---|---|---|

| Standard | ASTM D792 | ASTM D2240 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D624 | |

| Unit | g/cm3 | Shore A/D | MPa | MPa | MPa | % | KN/m | -- |

| HT380T | 1.23 | 84 | 25 | 7 | 10 | 90 | 500 | 108-1010 |

| HT385T | 1.23 | 85 | 30 | 10 | 12 | 95 | 400 | 108-1010 |

| HT390T | 1.24 | 93A | 35 | 12 | 15 | 110 | 350 | 108-1010 |

| HT480T | 1.15 | 80A | 23 | 7 | 11 | 80 | 500 | 108-1010 |

| HT485T | 1.15 | 87A | 28 | 10 | 15 | 90 | 400 | 108-1010 |

| HT490T | 1.2 | 90A | 32 | 13 | 18 | 100 | 350 | 108-1010 |

Note: The above values are shown as typical values and should not be used as specifications.

TPU Laser Marking Additive is a functional masterbatch designed to enable permanent, high-contrast laser marking on a wide range of thermoplastic materials. When exposed to laser irradiation, the additive reacts with the polymer matrix to generate clear, durable markings without damaging the surface or affecting mechanical properties.

Features:

Enhance mark contrast;

Increased Durability;

High Precision for intricate designs,small text, and detailed graphics;

Compatibility with TPU / TPE / TPV /ABS / SEBS / PVC;

Fast Processing and easy use.

Applications: Marking TPU livestock ear tags, TPU/TPE /TPR /PVC cables wires, and other molded plastic parts/shells.

Laser Marking Additives for Black Laser Marking on Colored Plastics

| Item | LYX-1032 | LYX-1042 | LYX-1052 | LYX-1062 | ||

|---|---|---|---|---|---|---|

| Dosage | 1%–4% | 1%–4% | 1%–4% | 1%–2% | ||

| Laser Type | Fiber Laser | Fiber Laser | Fiber Laser | UV Laser | ||

| Resin Compatibility | TPU | |||||

| Color | Ash White | Gray White | Gray | Whitish | ||

| Appearance | Pellet 2.5–3.0 mm | Pellet 5–6 mm | Pellet 2.5–3.0 mm | Pellet 2.5–3.0 mm | ||

| Melt Flow Rate | 10.0–25.0g/10min (190°C, 5kg) | |||||

| Density | 1.3–1.8 g/cm³ | |||||

| Bulk Density | 90–110 g/100 ml | |||||

| Heat Stability | Stable up to 280°C | |||||

| pH Value | 7–11 | |||||

| Certification | ISO9001, MSDS | |||||

| Packing Details | 25 kg/carton, Carton Size:500 × 380 × 160 mm | |||||

| HS Code | 3206499000 | |||||

| CAS No. | 1309-64-4 | |||||

| EINECS No. | 215-175-0 | |||||

| Purity | 98% | |||||

| Classification | Chemical Auxiliary Agent | |||||

Note: The above values are shown as typical values and should not be used as product standards.

TPU color masterbatch products are ideal for TPU coloring and pigmentation. These TPU coloring pellets and TPU pigment masterbatches ensure consistent color, excellent dispersion, and high-quality finish for all TPU-based products.

Features:

Excellent pigment dispersion

Maintains TPU elasticity & mechanical strength

Available in standard & custom colors (Pantone, RAL)

Suitable for injection molding, extrusion, and film applications

Applications:

Footwear soles and uppers

TPU ear tags and ID products

Soft material TPU parts

Medical devices & tubing

Consumer electronics TPU components

Laser Marking Additives for Black Laser Marking on Colored Plastics

| Product Name | Customized TPU Color Masterbatch |

|---|---|

| Forming Technology | Film Blowing, Injection Molding, Blow Molding, Extrusion, Thermoforming, Compounds Modification |

| Color | blue red yellow green purple or customized color |

| Dosage Ratio | 1%-5% |

| Appearance | Granule Pellets |

| Grain Size | 2.5-2.8mm |

| Pigment Content | 20-60% |

| Light Resistance | Grade 7 |

| Heat-Resistant | 180-250℃ |

| Density | 1.2~1.7g/cm |

| Melting Point | 210-220℃ |

| Weathering(level) | 4-6 |

| MFI | 10g-30g/10min |

| Color Intensity | 95-105% |

| Dosage Ratio | ≤0.5 |

| Migration Resistant(level) | 6-8 |

| Dispersal | ≤3 |

| Moisture Rate | <0.1% |

| Certificate | ISO9001 SMDS |

| Package | 25kg per package, Kraft Paper Bag with a carton |

| Customization | Materials can be customized with specific properties including glass fiber, carbon fiber, flame retardant, UV resistance, heat resistance, laser additive, toughness, MOS2, PMMA, and conductive materials. |