Processing methods:Injection, Extrusion, Calender, etc

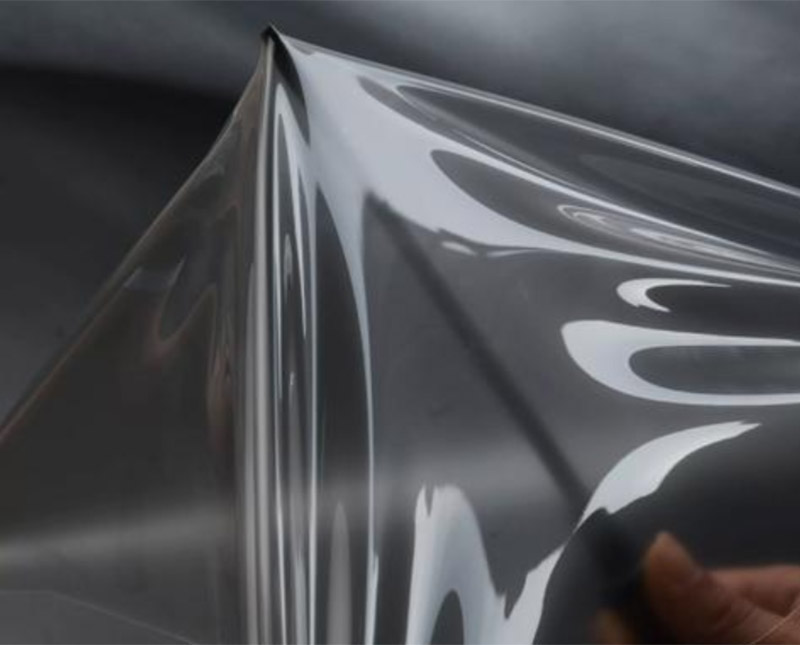

Features: No Yellowing on exposure to UV light, low temperature flexibility, high resilience, hydrolysis resistance, excellent transparency, anti-precipitation

Applications: Sports and Leisure Sectors, Automotive interior, Optical Glasses, Medical, pipes, cables, film sheets, paint protection film, smart wearables, etc.

| Properties | Density | Hardness | 100% Modulus | 300% Modulus | Tensile Strength | Elongation at Break | Tear Strength | Abrasion Resistance Loss |

|---|---|---|---|---|---|---|---|---|

| Standard | ASTM D792 | ASTM D2240 | ASTM D412 | ASTM D412 | ASTM D412 | ASTM D624 | ASTM D412 | ISO 4649 |

| Unit | g/cm3 | Shore A/D | MPa | MPa | MPa | KN/m | % | mm3 |

| 802 | 1.14 | 80 | 4 | 10 | 23 | 560 | 73 | 20 |

| 852 | 1.15 | 85 | 6 | 12 | 28 | 500 | 85 | 18 |

| 902 | 1.15 | 90 | 7 | 20 | 33 | 440 | 93 | 17 |

| 952 | 1.16 | 95 | 9 | 25 | 36 | 400 | 105 | 14 |

| 185 | 1.16 | 85 | 5 | 11 | 28 | 500 | 85 | 70 |

| 885 | 1.15 | 85 | 5 | 10 | 25 | 550 | 80 | 40 |

Note: The above values are shown as typical values and should not be used as specifications.